Home / Cruise Lines / Key Factors for Selecting Luxury Wholesale Hotel Linens

Are you struggling to find the perfect wholesale hotel linens that match the level of comfort, durability, and elegance your guests expect?

In today’s competitive hospitality industry, selecting the right linens is crucial to creating an unforgettable guest experience. This article will guide you through the key factors in choosing the best linens for luxury hotels, from understanding fiber content and fiber quality to decoding thread count and other important aspects. As a trusted supplier, 1Concier has been supporting premier hotels with exceptional luxury hotel linens that deliver both style and longevity. Read on to discover how we can help elevate your guest experience with our selection of luxury linens.

“Ultra-smooth sateen”

“High thread count”

“Combed cotton”

These are just a few of the marketing phrases that hotel linen suppliers use to sell customers on the luxury and quality of their wholesale hotel sheets. But what do such phrases really mean — if anything? And are the same factors important to both retail and hotel buyers? In this article, we’ll examine how luxury hotel linens are made and what features to look for to meet your needs.

Luxury Hotel Linens Start with the Yarn

When it comes to luxury hotel linens, the quality starts at the very beginning—with the yarn. The yarn’s composition, thickness, and overall quality have a significant impact on the feel, durability, and elegance of the finished product. High-quality yarns create fabrics that are smooth, soft, and resilient, offering guests a touch of indulgence they won’t soon forget. In this article, we’ll explore the process of selecting premium yarns, explaining why these first steps are essential to achieving the comfort and sophistication that discerning hotel guests expect.

Yarns — the strands that are woven into a fabric — make a fundamental difference to how well sheets look, feel and last. Even if a poor quality yarn is given high quality weaving and finishing treatments, the final product won’t live up to your expectations.

There are three factors to consider when judging yarn:

- what fiber it’s made of

- the quality of that fiber

- how it’s formed into the yarn.

Let’s look at each of these components.

Fiber Content for Luxury Hotel Linens

Fiber content is key to the softness and durability of luxury hotel linens.

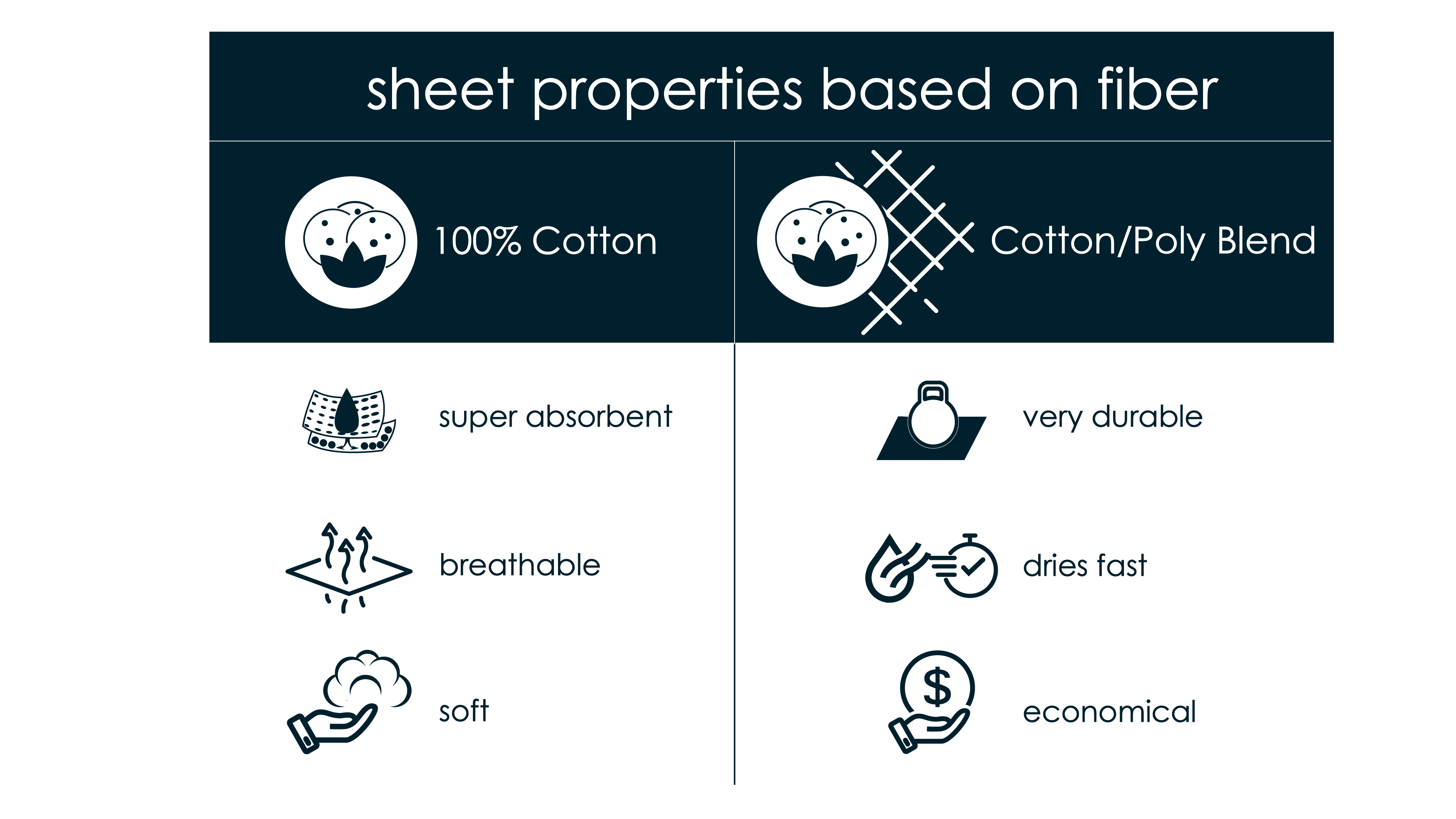

Fiber can come from a natural source such as cotton or be a manmade synthetic such as polyester. Each source brings different strengths and weaknesses to the finished luxury linens. For this reason, we often see blends of two or more fibers to maximize the strengths and offset the weaknesses.

Cotton is the most common fiber found in luxury hotel linens, because it provides excellent softness, breathability and moisture absorption. On the other hand, it is not particularly strong, meaning that it is susceptible to wear and tear; also, it is prone to wrinkling.

Polyester offers superior strength and wrinkle resistance. Its drawback is that it is less breathable and traps body heat. Thus, polyester is often twisted together with cotton to create blended yarns (e.g. 60% cotton/ 40% polyester). The softness and coolness guests love are combined with the durability a hospitality business requires.

Marketing messages promote 100% cotton hotel sheets as being better than blends. The reality, though, is that very few people can actually feel the difference. Even at high end hotels, guests think they’re sleeping on very expensive, pure cotton sheets, while very often these sheets are a good quality cotton/poly blend. Read our article about Cotton vs Cotton Poly towels to learn more.

A relatively new option on the sheets market is microfiber — a 100% polyester monofilament with an ultra-fine yarn. Microfiber fabrics mimic the hand of silk for a very sleek look and feel without the price tag. Because the yarn diameter is so small, it makes extremely dense, durable (yet supple) weaves, as we’ll discuss in the thread count section below.

Here’s a look at our microfiber sheets – Softwear Plus Collection

Fiber Quality of Luxury Hotel Linens

Cotton is especially subject to a wide variation in quality. To give consumers some of idea of what they are getting, terms such as “combed” and “long staple” are used. Here’s what they mean.

Combed cotton refers to the pre-spinning process of removing short threads, nubs and impurities — any little bits that would protrude from the surface of the yarn and make the finished textile feel less soft.

Long staple cotton has longer than average individual threads, which makes for a stronger yarn. This is a property of the cotton variety; Pima and Egyptian, cottons are known for their long staple. These types of cotton are mostly popular in retail, while the hospitality industry often uses Upland medium staple cotton. By blending medium staple cotton with polyester, the sheet gets extended life and durability while reducing cost.

Thread Counts for Luxury Hotel Linens

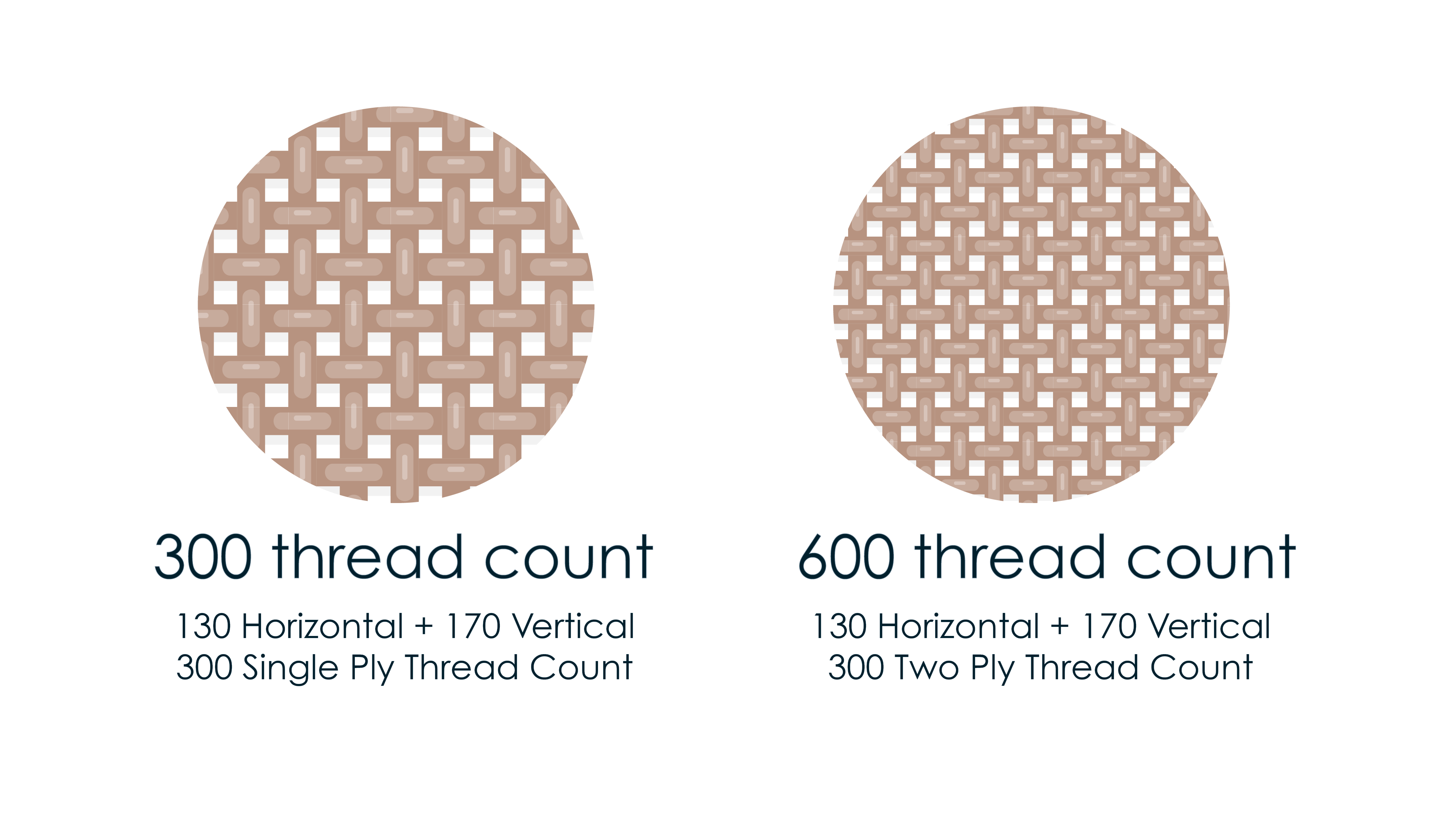

Thread count: the number of threads (yarns) per square inch of textile, counting both the warp (vertical) and weft (horizontal) threads. In theory, a higher count indicates a smoother, more durable fabric — say, a crisp, tight percale rather than a loose, unstable gauze.

This concept has been pushed more heavily to retail sheet consumers than any other. Higher thread count = higher quality, they are told. However, as many consumers have found to their discomfort, there are many ways to cheat at this game and produce a high thread count sheet that isn’t a much better quality. Manufacturers often use these tricks to increase their profit margins and inflate perceived value of product.

What thread count is the most popular in hotels?

The most popular thread count for hotel linens typically ranges between 200 and 300. This range offers an ideal balance of softness, durability, and breathability, ensuring comfort while withstanding frequent washes. Higher thread counts can provide a silkier feel, but mid-range counts are often preferred in hospitality for their resilience and luxurious touch. 1Concier offers a range of wholesale hotel linens from T200 to T490 providing options that suit various comfort levels, durability needs, and aesthetic preferences.

The Double Counting Cheat

When a fabric is woven with two-ply yarns, each yarn is supposed to count as one. However, some wholesale hotel linen suppliers count each ply within the yarn as one, thus doubling the advertised thread count. In this scenario, a sheet that’s really 300 thread count is claimed to be 600 thread count.

The Unfair Comparison

Because microfiber’s yarn is so much smaller than a cotton yarn can possibly be, the textiles it’s made with have with incredibly high thread counts. So comparing its thread count to cotton’s is an inaccurate way to judge overall quality. The optimum thread count, for feel-good, durability and value properties for hotels, is between 250 and 300. Anything over that will not improve customer experience enough to compensate for the increased cost.

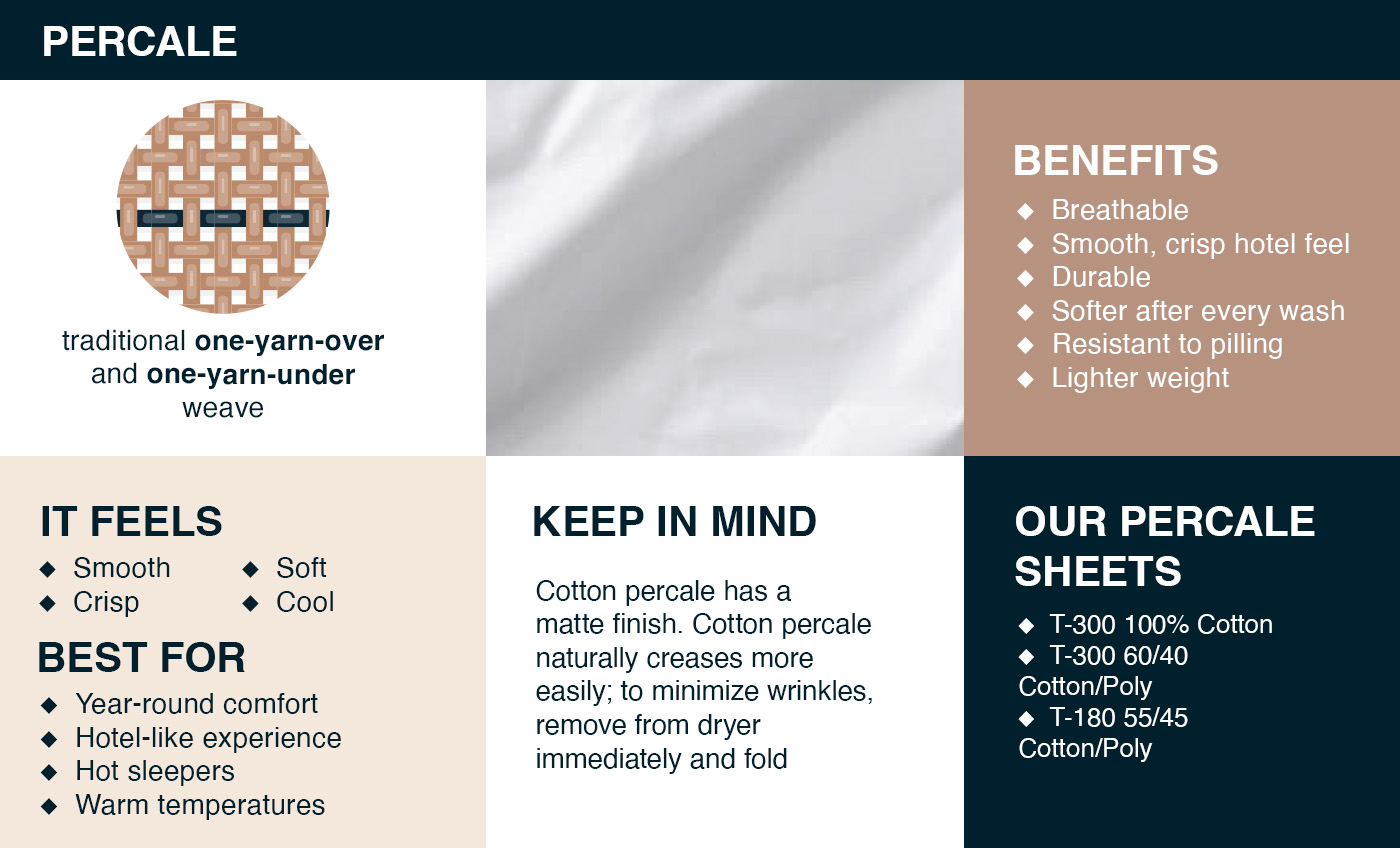

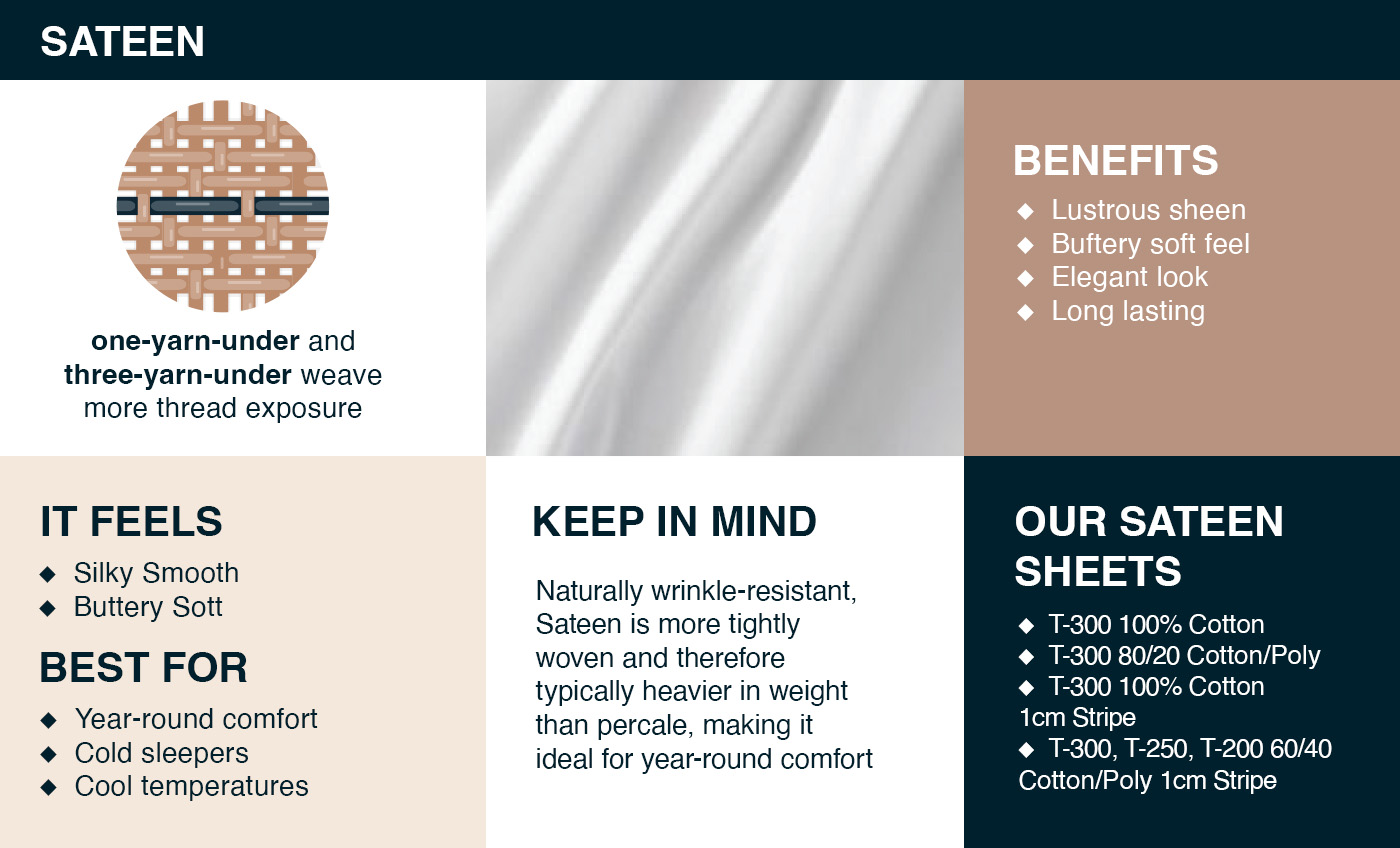

Sateen vs Percale Luxury Hotel Sheets

The final factor that contributes to wholesale hotel linens quality is weave. The two best weaves used for sheets in the hospitality industry are percale and sateen. Neither is better than the other; it’s a matter of personal preference.

Percale is woven with one yarn over, one yarn under. It is characterized by a matte finish, light weight and cool, crisp feel, a great choice for warm seasons/climates and hot sleepers. It is exceptionally long-wearing, getting softer with every wash without pilling.

How Do I Choose the Right Linens for My Business?

Choosing the right linens for your business involves considering factors like fiber content, thread count, durability, and the overall feel you want to provide for your guests. For hotels, long-staple cotton or blended fibers with a mid-range thread count (between 250 and 400) offer both luxury and resilience, ideal for frequent laundering. Event venues may prefer polyester blends for easy care and wrinkle resistance, while healthcare facilities need linens designed for high sanitation standards. 1Concier offers a wide selection of wholesale linens, from T200 to T490, tailored to various business needs, helping you find the perfect balance between quality, comfort, and durability.

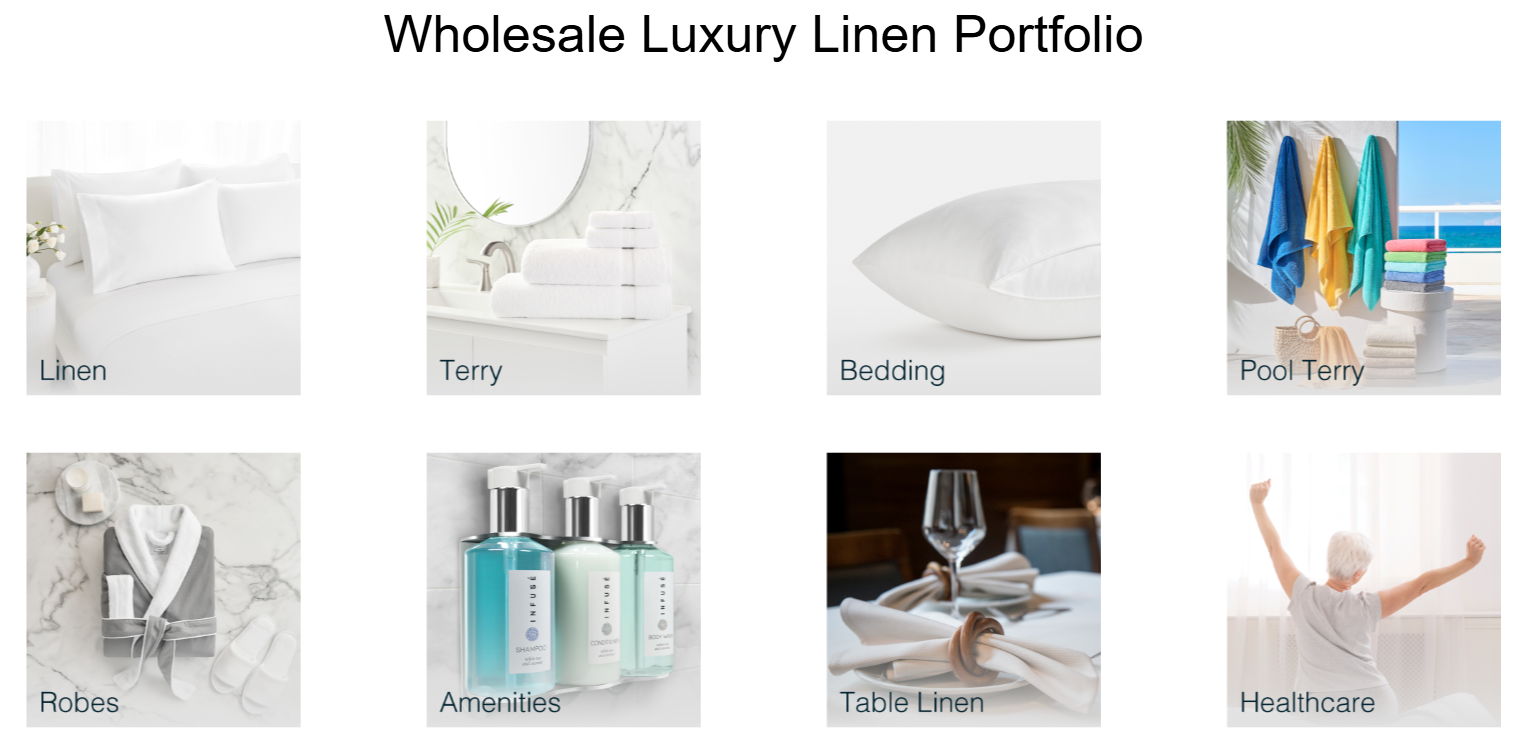

What Types of Linens Are Available for Wholesale?

Wholesale linens come in a variety of types to serve different industries, including bed linens (sheets, pillowcases, duvet covers), towels (bath towels, hand towels, washcloths), and table linens (tablecloths, napkins, runners) for hospitality and events. Additional options include bathrobes and slippers for luxury amenities, specialized healthcare linens for hospitals, and event linens like chair covers and drapes. Each type is crafted for durability and quality, meeting the unique needs of hotels, healthcare facilities, and event planners.

What Are the Benefits of Purchasing Linens in Bulk?

Purchasing linens in bulk provides significant cost savings, as wholesale pricing reduces the per-unit cost compared to smaller orders. It also ensures consistent quality and style across your inventory, enhancing your brand’s image. Additionally, buying in bulk allows for easier inventory management and ensures you have adequate stock to meet demand.

Where Can I Buy Wholesale Linens?

You can purchase wholesale linens from various wholesale hotel linen suppliers specializing in bulk textiles for industries such as hospitality, healthcare, and events. 1Concier is one of the top sources for luxury wholesale hotel linens, trusted by many leading brands, and we’re here to help you find the perfect linens for your business. Here are some other reputable wholesale linen suppliers:

Textile quality, budget, guest demographics and even your local climate play a role in deciding which sheets are right for your hotel. 1Concier is happy to help you with selection the perfect wholesale hotel linens, towels, pillows, blankets, pool towels, table linens, as well as identify how to layer your bed and set the right par level.

Table of Contents

Join the 1C Family as your Trusted Luxury Linen Provider

Featured Products

Choose from 14 Luxury Hotel Towel and Pool Towel Collections. We offer 100% Cotton, Cotton-Polyester blend, Pima, and Bamboo. From quick-drying absorbent towels to intricate borders and weaves, we have the right towel collection for you!

We offer a wide selection of luxury hotel sheets, bedding, blankets, and pillows in various qualities to suit your specific needs. Whether you’re looking for premium cotton sheets, soft and durable blankets, or plush pillows, we have options that ensure both comfort and elegance for your guests.

Our premium bathrobes can be found and many luxury hotels and spas, adding a touch of elegance and comfort to your guest experience. We also offer a range of guest room amenities.